Embark on a journey through the intricate process of retubing a tubular heat exchanger with Atlas Mechanical Services. Our meticulous overhaul guarantees peak performance and extended longevity for your equipment, ensuring optimal heat transfer efficiency.

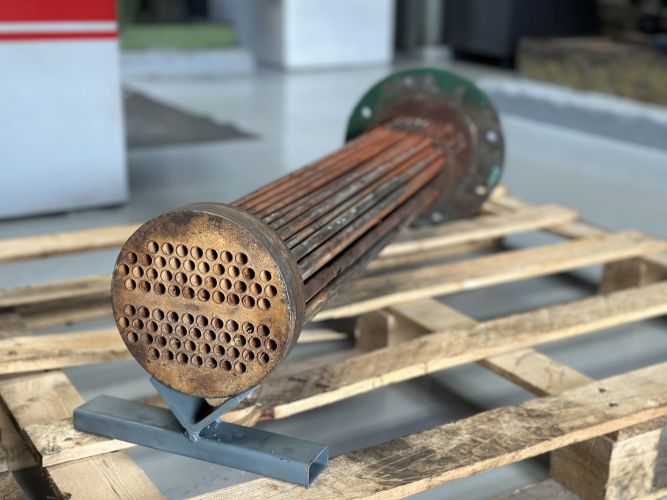

Precision Dismantling: We commence the retubing process with precision dismantling, delicately disassembling old tubes and removing them from tube sheets. Our skilled technicians ensure no damage is incurred to surrounding components during this critical phase.

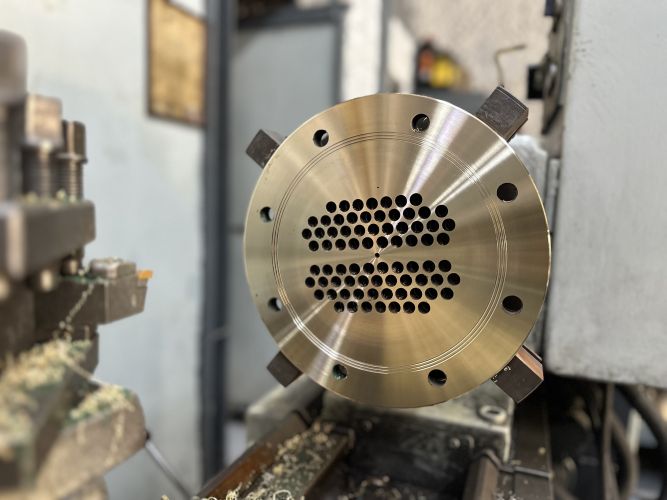

Expert Tube Sheet Refurbishment: Our experienced technicians meticulously refurbish tube sheets to like-new condition. This refurbishment process guarantees an optimal fit for new tubes, laying the foundation for efficient heat transfer within the exchanger.

Diaphragms Fabrication: Tailored to the specifications of the old ones, our craftsmen fabricate new diaphragms to ensure the correct water flow within the heat exchanger. This meticulous attention to detail ensures optimal performance and longevity.

Premium European-Certified Raw Materials: We pride ourselves on sourcing and customizing high-quality tubes from certified European materials. This commitment to quality ensures superior performance, reliability, and longevity for your heat exchanger.

Craftsman Assembly and Tube Expansion: Each tube undergoes meticulous assembly and expansion by our skilled craftsmen. Utilizing precise specifications, we ensure secure and efficient heat transfer without any compromise on integrity.

Thorough Pressure Testing: The final stage of our retubing process involves rigorous pressure testing. This step guarantees the integrity and reliability of the retubed heat exchanger, providing you with peace of mind regarding its performance under operating conditions.

Conclusion: With Atlas Mechanical Services' expertise in retubing tubular heat exchangers, you can trust in the enhanced performance and extended longevity of your equipment. Our commitment to precision, quality materials, and rigorous testing ensures that your heat exchanger operates at its peak efficiency, meeting the demands of your industrial processes with ease.