Heat Exchangers

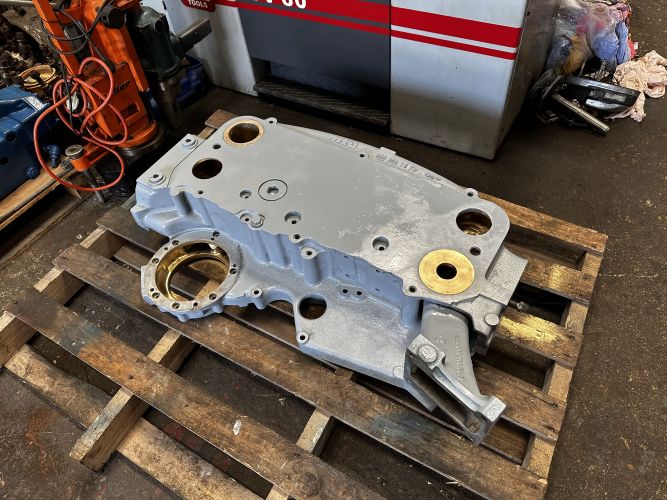

Our company specializes in the manufacture of heat exchangers for 40 years, using European raw materials for the appropriate use.

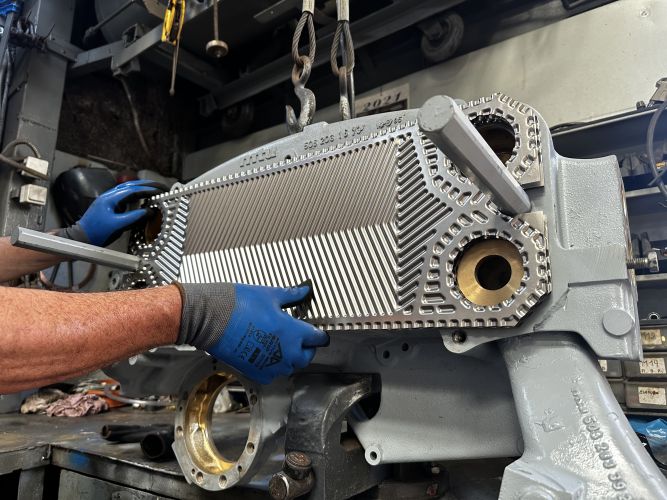

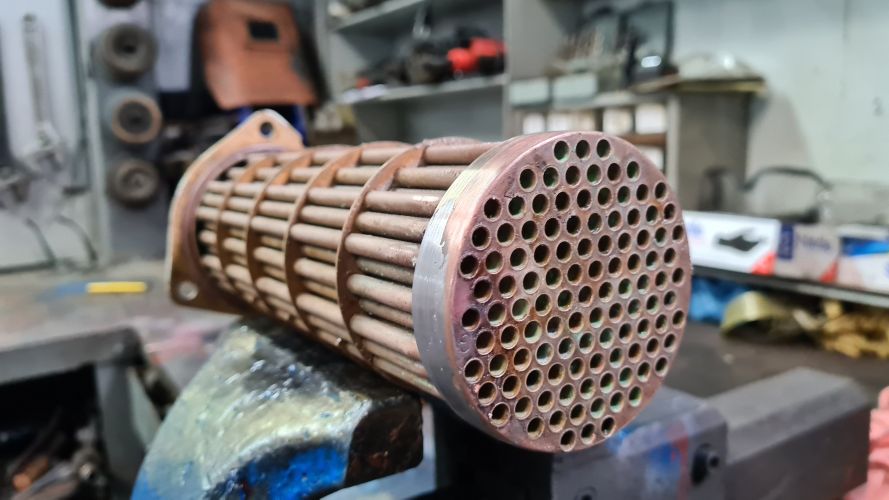

Our experience in the field of repair of heat exchangers (tubular or gasket plate coolers), makes us one of the best choices in terms of quality, cost and delivery time.

The cleaning in the main areas of flow of liquids or gases in the shells, as well as in the coolers, are done with special chemicals friendly to the construction material.

In this way, the maximum possible quality of cleaning is achieved, in order to ensure the full amount of flow in the traffic areas.

Through hydraulic pressure tests, we detect and locate the sources of any leaks or diagnose the absolute seal of the heat exchanger.

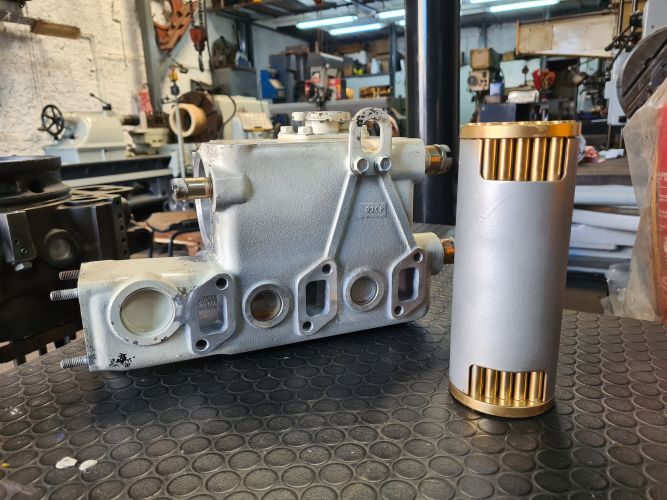

Worn faces, leaks and corroded cells from time of use are not irreparable damage.

We recondition worn faces and corrosion on the bodies that cause leaks, restoring the original dimensions as well as the complete sealing.